Product

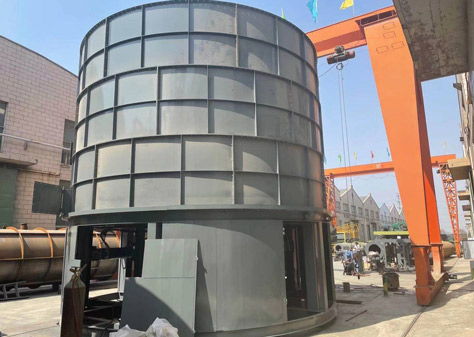

Vertical Organic Fertilizer Fermentation Tank

PRODUCT DETAILS

The fertilizer fermentation tank equipment can be used for treating organic waste such as pig manure, chicken manure, cow dung, sheep manure, mushroom residue, Chinese medicine residue, crop straw, etc., occupying less land, no pollution (Closed fermentation), completely killing pests and eggs (can be adjusted to 80-90 ° C high temperature), is the best choice for the majority of aquaculture enterprises, recycling agriculture, ecological agriculture to achieve waste resource utilization. In addition, we can customize 5-100m³ different capacity fermenters according to customer needs.

|

Model |

Heating Power(kw) |

Stirring Power(kw) |

Dimensions(mm) |

|

TDFJG-5 |

4*6 |

7.5 |

2200*2200*5300 |

|

TDFJG-10 |

4*6 |

11 |

2400*2400*6900 |

|

TDFJG-20 |

8*6 |

18.5 |

3700*3700*8500 |

|

TDFJG-30 |

58 |

7.5 |

4200*4200*8700 |

|

TDFJG-90 |

58 |

7.5 |

5300*5300*9500 |

The basic technological process of organic fertilizer fermenting tank is divided into feeding, aerobic fermentation, discharging, and resource utilization (organic fertilizer raw materials). The whole process has high active level and strong sealing.Organic fertilizer fermenter an environmental protection equipment, using the decomposition of microorganisms in nature, after 7 days or so in the closed fermenter continuous aerobic fermentation, the organic solid waste by microbial fermentation, deodorization and rot, processing into chicken manure organic manure.

Organic fertilizer fermentation tank raw materials:

1. Agricultural wastes: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.

2. Livestock and poultry dung: such as chicken dung, cow, sheep and horse dung, rabbit dung;

3. Industrial waste: such as distiller’s grains, vinegar grains, cassava residue, sugar residue, furfural residue, etc;

4. Domestic waste: such as kitchen waste;

5. Urban sludge: such as river sludge, sewage sludge, etc. Classification of organic fertilizer raw materials: mushroom dregs, kelp dregs, phosphocitric acid dregs, cassava dregs, sugar aldehyde dregs, amino acid humic acid, oil dregs, shell powder and peanut shell powder.

The basic technological process of organic fertilizer fermenting tank is divided into feeding, aerobic fermentation, discharging, and resource utilization (organic fertilizer raw materials). The whole process has high active level and strong sealing.Organic fertilizer fermenter an environmental protection equipment, using the decomposition of microorganisms in nature, after 7 days or so in the closed fermenter continuous aerobic fermentation, the organic solid waste by microbial fermentation, deodorization and rot, processing into chicken manure organic manure.