Product

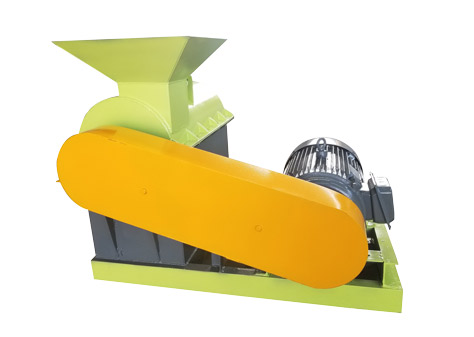

Fertilizer Semi-Wet Material Crusher

PRODUCT DETAILS

Semi-wet material pulverizer is a professional pulverizing equipment for professional pulverizing high humidity and multi-fiber materials. The semi-wet material pulverizer uses a high-speed rotating blade to pulverize the fiber with good particle size, high efficiency and high energy. The semi-wet material pulverizer is mostly used in the production and processing of organic fertilizer, and the smashing of chicken manure, humic acid and other raw materials has a good effect.

|

Model |

Power(kw) |

Capacity(t/h) |

Crushing Granularity(mesh) |

Inlet Size(mm) |

Dimensions(mm) |

|

TDSF-40 |

22 |

1-1.5 |

50 |

400*240 |

1200*1350*900 |

|

TDSF-40(new) |

22*2 |

1-1.5 |

80 |

400*240 |

1250*1600*1300 |

|

TDSF-60 |

30 |

1.5-3 |

50 |

500*300 |

1300*1450*1300 |

|

TDSF-60(new) |

30*2 |

1.5-3 |

80 |

500*300 |

1500*2150*1920 |

|

TDSF-90 |

37 |

3-5 |

50 |

550*410 |

1800*1550*1700 |

|

TDSF-120 |

75 |

5-8 |

50 |

650*500 |

2100*2600*2130 |

- The semi-wet material crusher has flexible combination and strong applicability.

- The semi-wet material crusher does not have any requirement for the moisture content of the material. Without the sieve bottom and the screen mesh, the material with high moisture content can be pulverized, and the viscous material with relatively high viscosity will not be clogged.

- The semi-wet material crusher uses a high-alloy wear-resistant hammer head. The hammer piece is made of forged, which is particularly strong and wear-resistant. It is stronger than the ordinary hammer and increases the service life of the hammer piece.

- The semi-wet material crusher adopts the gap-fixing technology. When the hammer head is worn, the position of the hammer head is adjusted to reduce the gap between the hammer and the lining. This will give you a satisfactory graininess.

The semi-wet material pulverizer adopts the two-stage rotors, that means up and down two-stage pulverization. When he raw material passes through the upper-stage rotor pulverizer to form a coarse particles, and then is transported to the lower-stage rotor to continue pulverization into fine powder to reach the best particle sizes for the next granulating device. There is no sieve mesh at bottom of the semi-wet material pulverizer. wet materials can be crushed and never blocked. Even materials that have just been taken from the water can be crushed, and no worry about clogged or blocked.