Product

Cattle Manure Organic Fertilizer Production Line

PRODUCT DETAILS

Product introduction

- Cattle manure organic fertilizer production line is a complete set of equipment for processing organic fertilizer with cow manure as raw material. Cattle manure can be pumped into the equipment by a cow manure treatment machine through a slurry pump. After dehydration, the water content after treatment is about 40%. It can also be filled with crops such as straw and rice bran (containing NPK). Then it is sprayed with biological bacteria seed agent, 1KG bacterial seed agent mixed with 20KG water. It can ferment 1 ton of raw material when it is moved into the raw material. Turn over once every 1-2 days, usually 7-10 days can be completely decomposed.

- In recent years, the pollution of livestock and poultry manure and urine and the residue of livestock and poultry products pose a problem to human health. Pollution from livestock and poultry farming has become the main source of pollution in rural areas of China. The huge data of livestock and poultry production can not be ignored. If not handled properly, it will cause serious pollution to the environment.

- For example, due to the lack of timely treatment of livestock and poultry manure, surface water, groundwater, soil and air will be seriously polluted. What is more serious is that small-scale maintenance households simply stack beef cattle dung beside the highway for the convenience of transportation, without adopting a scientific storage method. Due to neglect of management, wind and rain, the excrement flows everywhere. Such a situation is not conducive to the requirements of animal epidemic prevention, but also will have a certain impact on people’s living environment.

The Main Technical Parameters

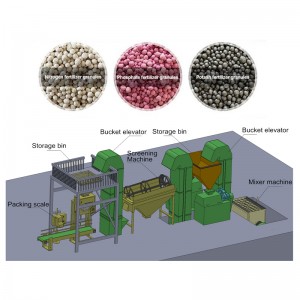

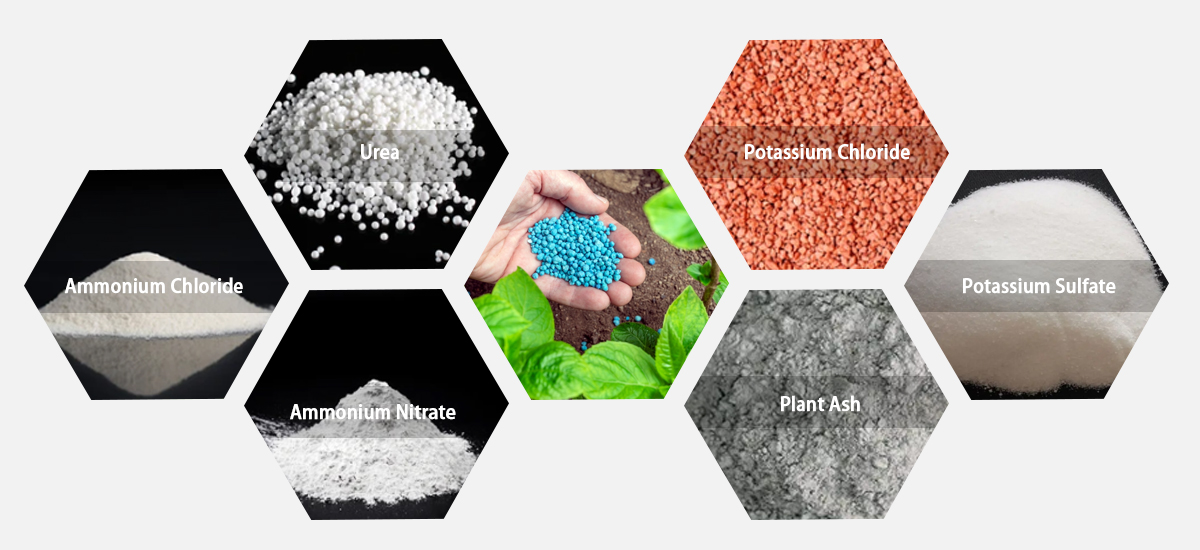

- Fermentation of raw materials: chicken manure, pig manure, cow manure, biogas residue and other animal manure can be fermented or processed with fertilizer-efficient raw materials in a certain proportion (according to market demand and soil test results in different places).

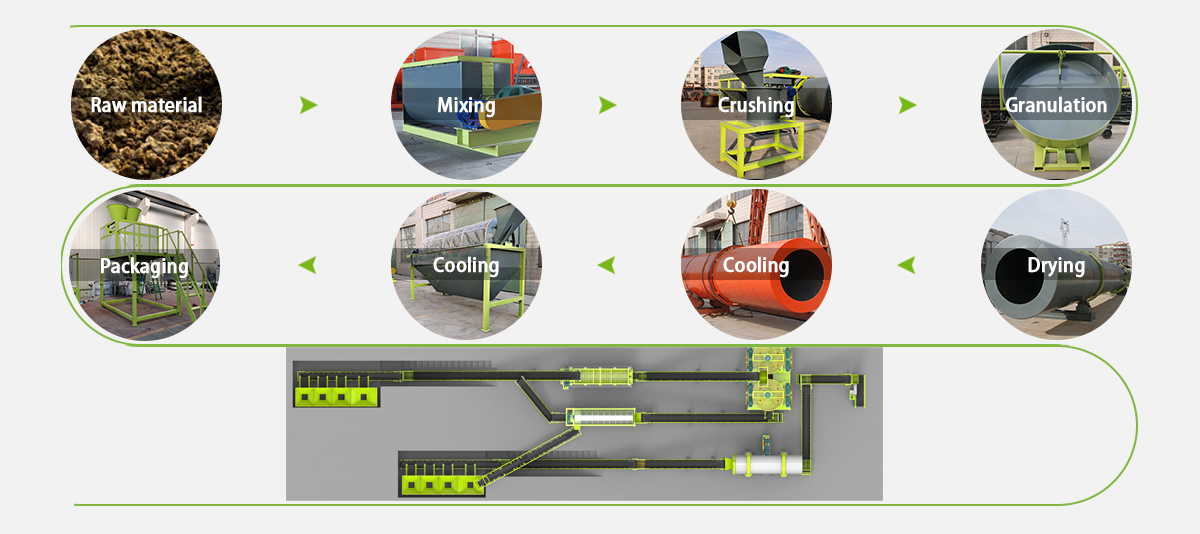

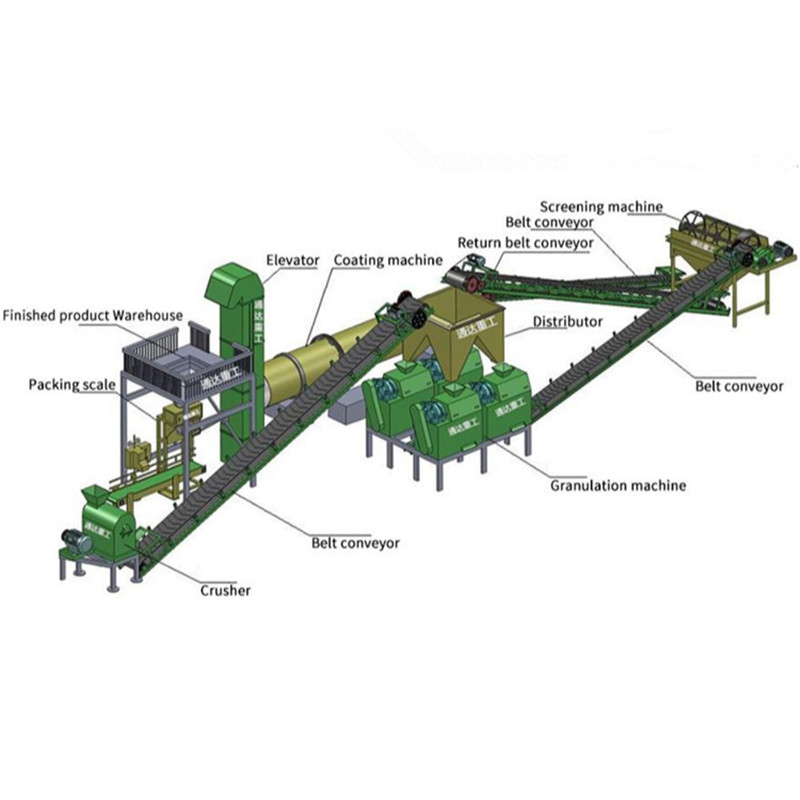

- Material mixing: mixing the raw materials evenly to improve the uniform fertilizer efficiency of the whole fertilizer granule.

- Material granulation: Feed the uniformly stirred material into the granulator for granulation (drum granulator or extrusion granulator can be used).

- Particle drying: The granulator is fed into the dryer, and the moisture contained in the granule is dried to increase the strength of the granule and to facilitate its preservation.

- Particle cooling: After drying, the temperature of fertilizer particles is too high and easy to agglomerate. After cooling, it is easy to store and transport in bags.

- Particle Classification: After cooling, the particles are classified. The unqualified particles are crushed and re-granulated, and the qualified products are screened out.

- Finished product coating: coating qualified products to increase the brightness and roundness of particles.

- Packaging of finished products: Film-coated particles, i.e. finished products, are packed and stored in a ventilated place.

Performance characteristics

- Organic fertilizer production line equipment, compact process layout, scientific and rational, advanced technology, energy saving, consumption reduction, no three emissions, stable operation, reliable operation, convenient maintenance, wide adaptability of raw materials.

- Organic compound fertilizer, bio-organic fertilizer, municipal sludge and domestic garbage organic fertilizer, which are suitable for various proportions, have filled the domestic blank and occupied the leading level in China.

- Chicken manure is a national environmental protection practical technology promotion project, which is rich in organic matter, can provide nutrients needed for crop growth, and can fertilize and improve soil.

- There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also changing rapidly.

Working principle

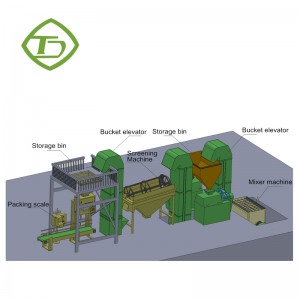

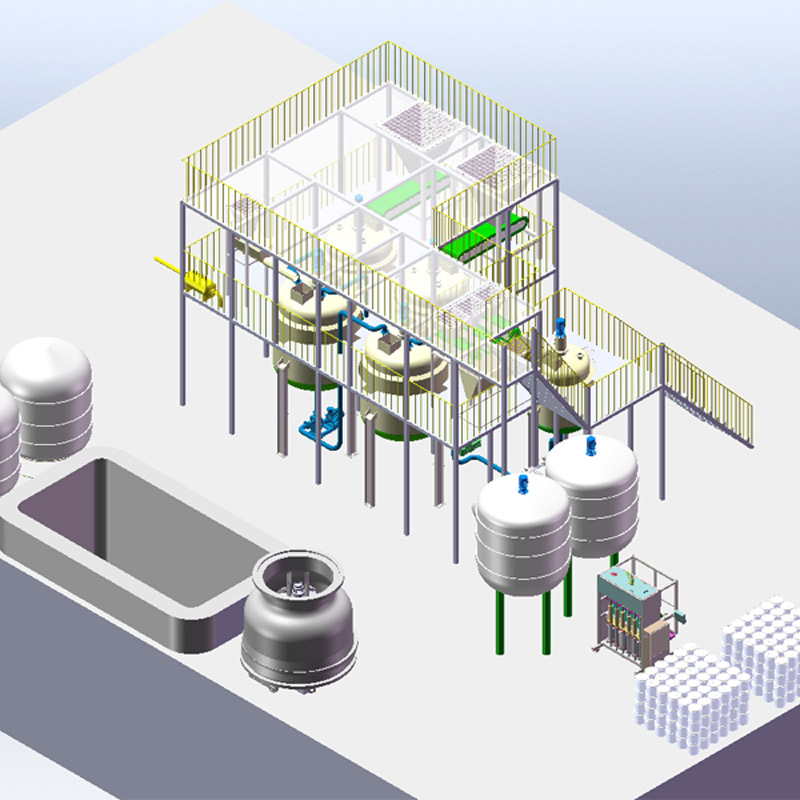

Organic fertilizer production process is closely related to the equipment configuration of organic fertilizer production line. Generally, the complete equipment of organic fertilizer production line consists of fermentation system, drying system, deodorization and dust removal system, grinding system, ingredient system, mixing system, granulation system, cooling and drying system, screening system and finished product packaging system.

Following is a detailed description of the equipment requirements of each link system in the organic fertilizer production process:

- Fermentation system of organic fertilizer production process consists of feeding conveyor, biological deodorizer, mixer, proprietary lifting dumper and electric automatic control system.

- Drying system: The main equipment of drying system includes belt conveyor, drum dryer, cooler, induced draft fan, hot stove, etc.

- Deodorization and dust removal system: Deodorization and dust removal system is composed of settling chamber, dust removal chamber and so on. Access to Heavy Industry provides free drawings and free guidance for users to build

- Crushing system: The crushing system includes a new semi-wet material crusher produced by Zhengzhou Tongda Heavy Industry, LP chain crusher or cage crusher, belt conveyor, etc.

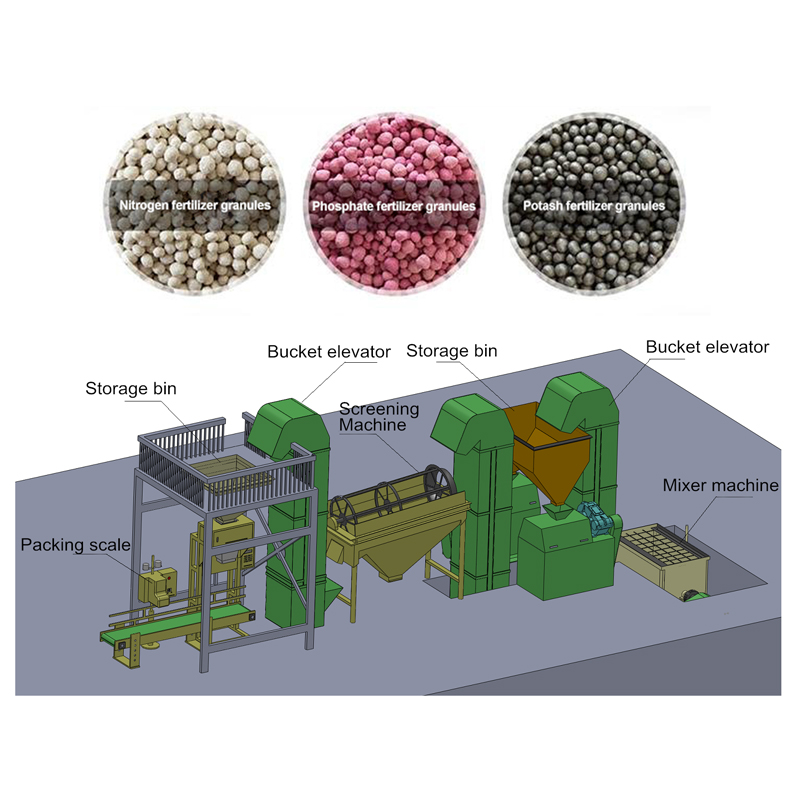

- The proportioning system of the proportioning system includes electronic proportioning system, disc feeder and vibrating screen, which can configure 6-8 kinds of raw materials at a time.

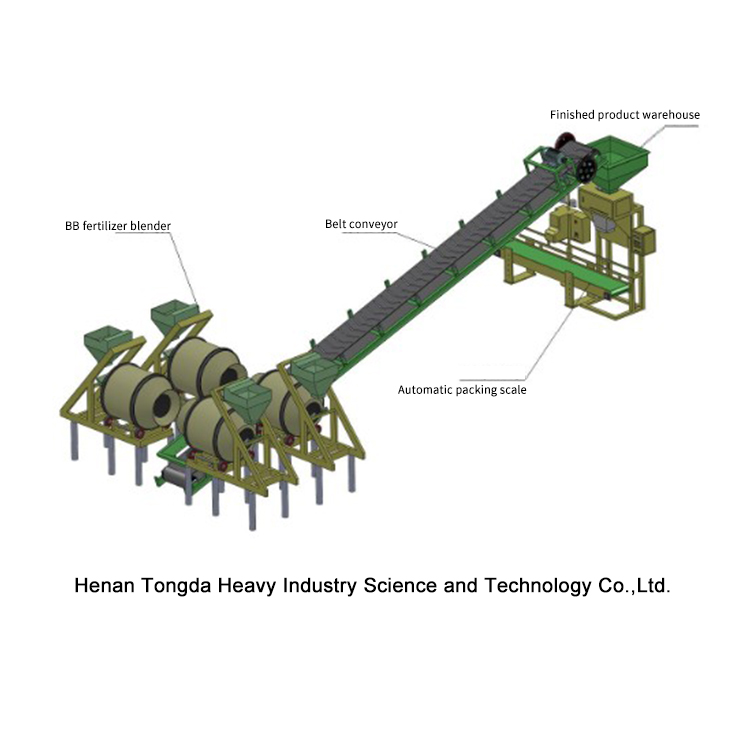

- The mixing system of the mixing system consists of a horizontal mixer or a disc mixer, a vibrating screen, a movable belt conveyor, etc.

- The optional granulator equipment, the granulator system of the organic fertilizer production process, needs the granulator equipment. The optional granulator equipment includes: compound fertilizer roller extruder granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer granulator, drum granulator, thrower, compound fertilizer granulator, etc.

- The cooling and drying system of the cooling and drying system can be used in rotary dryer, drum cooler and other equipment for drying and cooling.

- Screening system screening system is mainly completed by drum screening machine, which can set up a first-level screening machine and a second-level screening machine, so that the yield of finished products is higher and the particles are better.

- Finished product packaging system Finished product packaging system generally includes electronic quantitative packaging scale, warehouse, automatic sewing machine and so on. In this way, the full automatic and uninterrupted production of organic fertilizer production line can be realized.